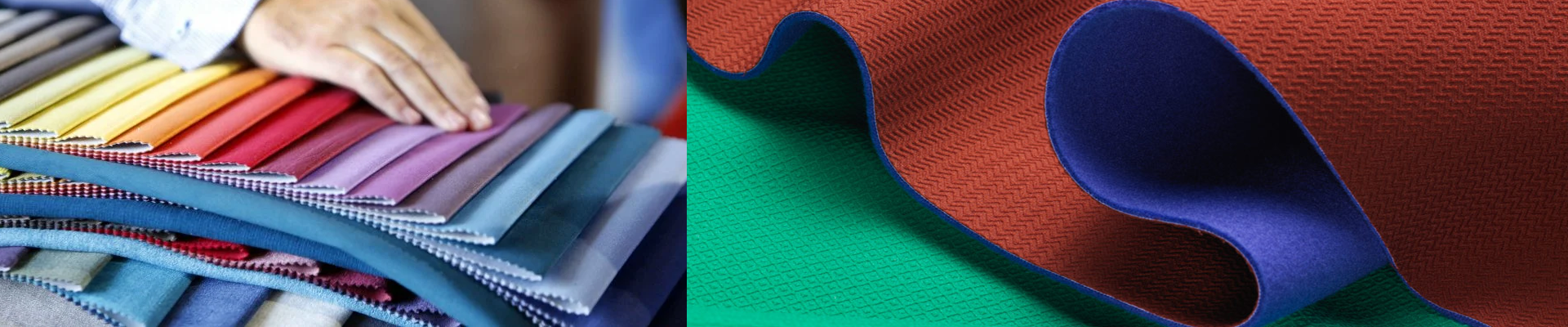

Our R&D department works daily in the research and study of new trends, raw materials, and production techniques, offering our customers special access to the most vibrant novelties, and expanding market and product diversification.

Planning and purchasing of raw materials are two departments that operate transversally across our Company’s activities. We have full control of our raw material needs, as well as real-time management of our internal supply chain and relationship with outsourced resources. Trims are extremely valuable on a garment. We have a department dedicated to the development, purchase, and handling of trims. Permanently in line with our customers, we are constantly searching, developing, and suggesting all kinds of accessories to add value to their garments.

We believe that pattern-making is an art. It is the art of manipulating and shaping a flat piece of fabric to conform to one or more curves of the human figure. Pattern-making is a bridge between design and production. Our patterns department has a team of experienced and committed pattern makers who, assisted by the GGT-CAD and Echo-CAD systems, develop a work that is key to the quality and adequacy of the final product.